Solutions

Our range of reactors is tailored to the specific needs of each project, with one range for low consumption and another for those requiring larger volumes. Hydrogen generation capacity can go from 1kW in the lower range to several MW in the upper one, taking advantage of the scalability of our products.

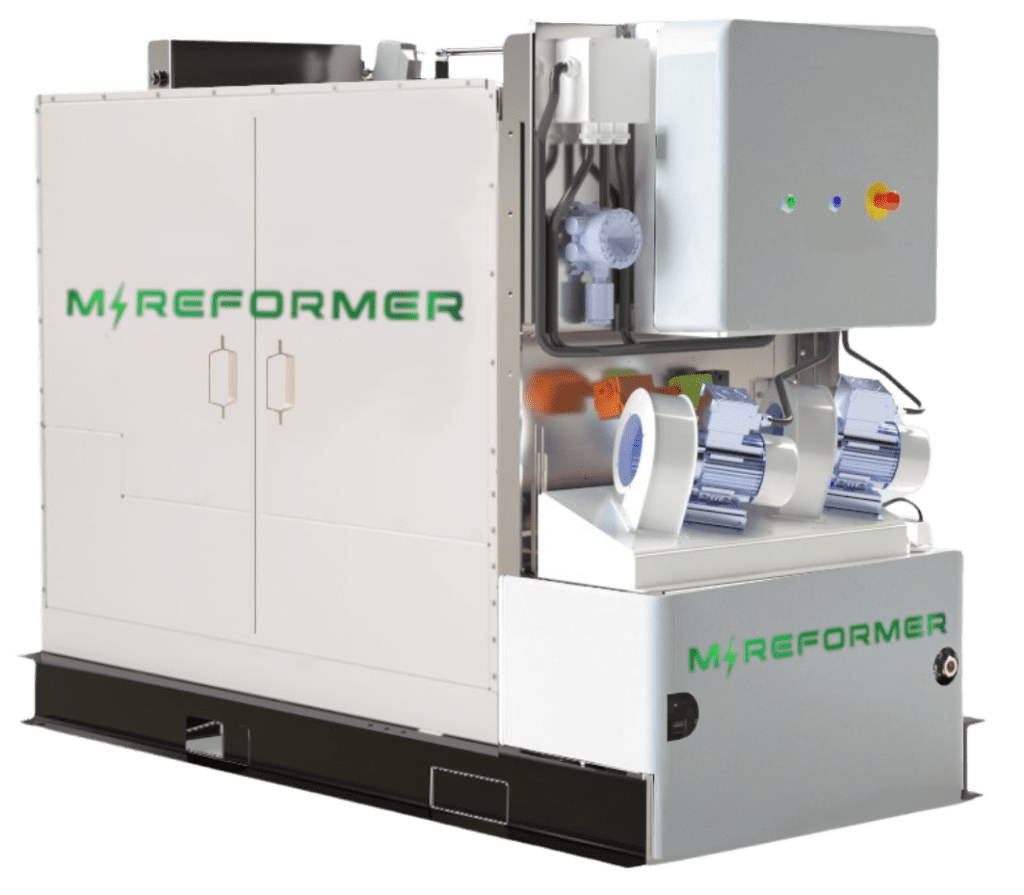

Medium (M18)

Capacity from 9,8 kG/hr

Scalable high-capacity hydrogen generation modules for large consumers.

The M series is aimed at Mobility applications, especially in trains and FCEV trucks where it replaces high pressure hydrogen cylinders.

The L series is focused on stationary applications, where it becomes an attractive alternative versus hydrogen generation systems by hydrolysis, providing a solution with low investment costs (Capex) and lower operating costs (Opex).

It is best suited for hydrogen recharge stations (HRS) and/or combined charging stations (CCS) where high generation capacities are required.

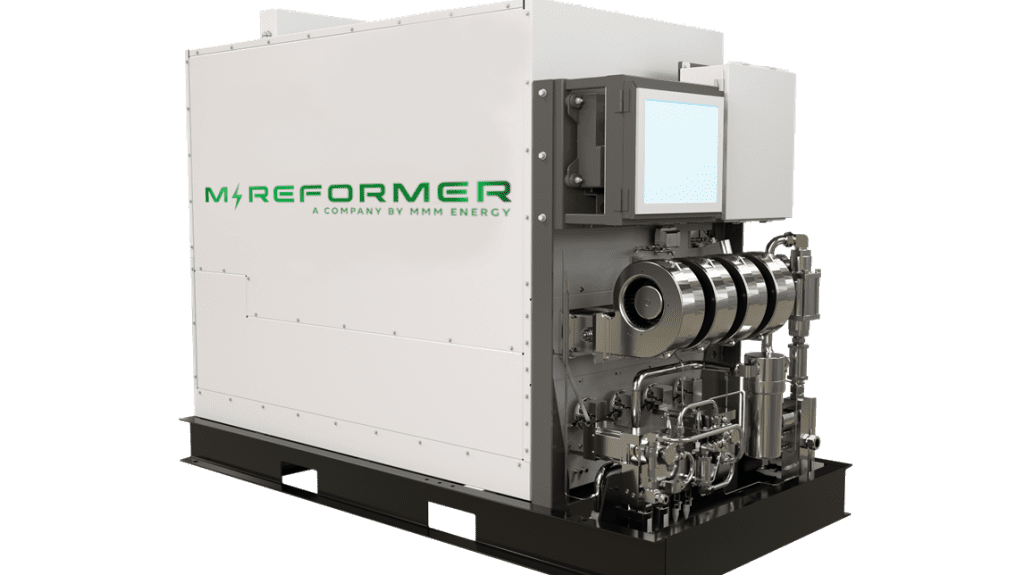

High Power (M30)

Capacity from 16,2 kG/hr and above

Scalable high-capacity hydrogen generation modules for large consumers.

The M series is aimed at Mobility applications, especially in trains and FCEV trucks where it replaces high pressure hydrogen cylinders.

The L series is focused on stationary applications, where it becomes an attractive alternative versus hydrogen generation systems by hydrolysis, providing a solution with low investment costs (Capex) and lower operating costs (Opex).

It is best suited for hydrogen recharge stations (HRS) and/or combined charging stations (CCS) where high generation capacities are required.

Discover MReformer solutions at www.methanolreformer.com

Some of the main advantages of our methanol reactors

Environmentally friendly

Reduce CO2 emissions by 28% with zero emissions of particulate pollutants in the case of fossil methanol and in the case of green methanol its operation achieves carbon neutrality.

Low operating cost (Opex)

Always related to the acquisition cost of methanol, the cost is usually lower than that of packaged and transported industrial hydrogen and the cost of electricity consumption of the electrolyzers.

Low capital expenditure (Capex)

Especially when compared to the investments required to implement electrolyzer systems.

Modulars

Additional units are simply added to match supply to demand. Scalable from 1 kW to several MW.

Reliable and low maintenance

Sturdy design with no moving parts to cause wear and tear, the units are equipped with advanced, fully automated control systems that also allow remote monitoring.

Vibration resistant

Particularly suitable for mobile applications.

Long service life

The consumables (catalyst and H2 filter membrane) have a service life of approximately > 20,000 operating hours for the filter membrane and > 40,000 for the catalyst.

Fast hydrogen availability

From hot standby mode, the M/L series takes less than 3 minutes to start hydrogen supply.

Contact the Energy Systems team.

If a complete turnkey solution including fuel cell power generation is required, our engineering department can provide a technical and economic proposal that meets the customer’s specifications.