Additive manufacturing with high-performance technical materials

We offer industrial scale additive manufacturing solutions for unique and specialized needs according to your requirements.

We help you identify those areas of your value chain where additive manufacturing can have the greatest impact and add the most value.

We have teams of specialized engineers to help you analyze your designs for optimal results.

With our technology and experience we can find the best solution to meet your needs through 3D printing.

3D printing in reinforced polymers and metal

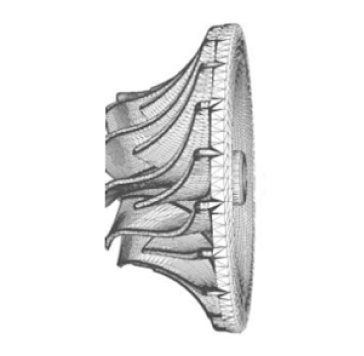

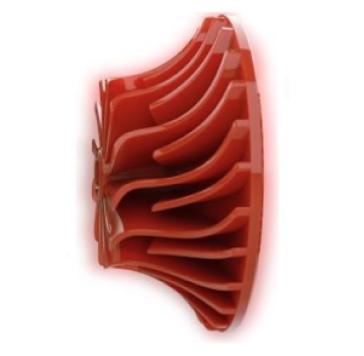

Fibre-Reinforced Plastic Solutions

They adequately replace parts made of traditional plastics (ABS, nylon, PDA, polypropylene, etc.).

Materials

Base Material: Onyx (Nylon + carbon fibre)

Onyx is a nylon filled with carbon fibre micro particles.

- 1,4 times more tear resistant than ABS (40Mpa)

- 1.4 times more rigid than ABS

- It has different reinforcement possibilities between layers

The addition of the following reinforcements improves the adhesion between layers.

Carbon fibre reinforcement

- 2.5 times more breaking strength (up to 590 Mpa)

- 8 times more rigid

Glass fibre or Kevlar reinforcement

- Increased fatigue resistance

- Higher breaking strength (from 590 to 610 Mpa)

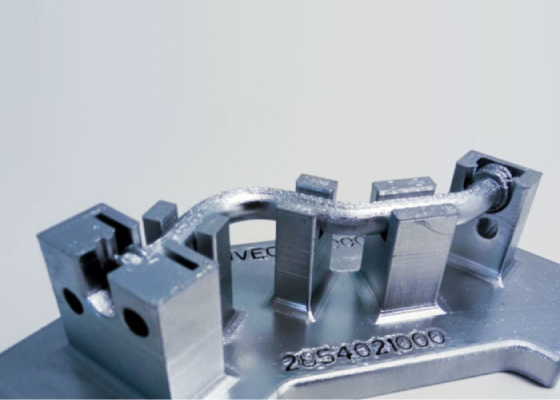

Heavy-Duty Metal Solutions

For long-lasting components withstanding heavy wear, high temperatures or aggressive corrosive environments.

Materials

Stainless steel 17-4 PH

- Multi-purpose stainless steel for industrial applications

- Heat treatment up to 36 HRC

- Breaking strength of 1250

H-13 tool steel

- Harder than 17-4 PH steel

- Retains its properties at high temperatures

- Characteristics compatible with many applications

- Heat treatment up to 45 HRC

- Breaking strength of 1500 Mpa

Inconel 625 steel

- Nickel-Chromium based superalloying

- Corrosion and high temperature resistant

- Meets ASTM B443 chemical requirements

- Breaking strength of 600 Mpa at 600 ºC

3D printing of jigs, toolings and other unique components is ideal for projects with:

- The need for highly specialized products .

- Significant reduction of the development and production times of the final part.

- Need for flexibility during the design process and in manufacturing.

- Need to reverse engineer a CAD model and increase its value through 3D printing.

Stages in the design and manufacturing process

Fibre-reinforced plastic printing process

The process is simple as the part is ready for either an aesthetic finish or any other post-processing.

Sintered metal printing process

In this case, the piece must go through several processes after printing:

- Washing: the remains of the wax binder are removed before going into the sintering furnace.

- Sintering: the piece is heated in a special furnace to increase the density of the material.

- Machining or heat treatment: depending on the application, heat treatment or machining can be carried out.